Factors Affecting Deck Beam Span

Decks are a versatile addition to any home, offering an outdoor space for relaxation, entertainment, and enjoyment. However, constructing a safe and durable deck requires careful planning, particularly when it comes to the structural components. One of the most critical elements is the deck beam, which supports the joists and the load of the deck. Understanding the factors that affect deck beam span is essential for ensuring that your deck meets safety standards and functions effectively.

What is Deck Beam Span?

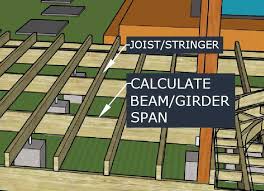

deck beam span chart refers to the maximum distance a beam can safely span between two support points, such as posts. The span length is determined by several factors, including the size and type of the beam, the load it must carry, and the spacing of other structural elements. An improperly sized beam can compromise the structural integrity of the deck, leading to sagging, instability, or even collapse.

To determine the appropriate beam span for your deck, it is necessary to consider several factors. Below are the key variables that influence beam span and how they interact to create a stable and functional structure.

- Type and Grade of Wood

The type of wood used for the beam plays a significant role in determining its strength and load-bearing capacity. Different species of wood have varying levels of density, strength, and durability. For instance:

- Southern Pine: Known for its high strength, Southern Pine can span longer distances compared to other wood types.

- Douglas Fir: While slightly less strong than Southern Pine, Douglas Fir is a popular choice for its balance of strength and cost.

- Redwood and Cedar: These species are more resistant to rot and decay but typically have lower strength, requiring shorter spans.

The grade of the wood, which indicates its quality and the presence of knots or defects, also affects its performance. Higher-grade lumber can span longer distances safely.

- Dimensions of the Beam

The size of the beam directly impacts its ability to span longer distances. Beams are typically described by their width (“2x”) and depth (e.g., 2×8, 2×10, 2×12). Depth has a more significant effect on the span length than width. For example, a 2×12 beam can span considerably farther than a 2×8 beam due to its greater depth, which provides more resistance to bending under load.

- Joist Spacing

The spacing of the joists supported by the beam also affects the maximum span. Joists are typically spaced 12 inches, 16 inches, or 24 inches apart. Closer spacing reduces the load on the beam, allowing it to span longer distances. Conversely, wider spacing increases the load per unit area, reducing the allowable span.

- Deck Load Requirements

Decks are designed to support two types of loads:

- Dead Load: This is the weight of the deck structure itself, including the beams, joists, decking, and any attached features like railings.

- Live Load: This includes temporary weight from people, furniture, and other movable items. For residential decks, building codes typically require a live load of 40 pounds per square foot and a dead load of 10 pounds per square foot.

Beams must be sized to support the combined total load. Higher load requirements will reduce the maximum allowable span.

- Number of Plies

Deck beams can consist of one, two, or more plies of lumber fastened together to increase strength. A double-ply or triple-ply beam can span longer distances than a single-ply beam of the same size. For instance, a double 2×10 beam can span farther than a single 2×10 beam under the same conditions.

- Support Post Spacing

The distance between the support posts directly affects the beam span. More frequent posts reduce the length of the span, increasing the beam’s load-bearing capacity. For longer spans, additional posts or larger beams are required.

- Environmental Conditions

External factors such as weather and climate can impact the performance of deck beams. Areas with high humidity, heavy rainfall, or extreme temperatures may require treated or engineered wood to resist decay and maintain structural integrity. Snow loads and wind loads must also be considered in regions prone to these conditions, as they add to the deck’s overall load.

- Use of Engineered Lumber

In addition to natural wood, many builders use engineered lumber, such as laminated veneer lumber (LVL) or glulam beams. These materials are designed to be stronger and more uniform than traditional wood, allowing for longer spans with smaller dimensions. However, engineered lumber often comes at a higher cost.

- Building Codes and Regulations

Local building codes specify minimum requirements for deck construction, including beam span limits. These codes are based on safety standards and may vary depending on your location. It is crucial to consult your local building department and adhere to these guidelines to ensure compliance and pass inspections.

Practical Example

Let’s consider a scenario where you are building a residential deck using a double 2×10 Southern Pine beam. The joists are spaced 16 inches apart, and the deck is designed for a total load of 50 pounds per square foot. Referring to span tables or charts, you find the following:

- For a beam span of 8 feet, the double 2×10 beam is adequate.

- For a span of 10 feet, the beam approaches its maximum safe limit.

- For spans longer than 10 feet, you would need a double 2×12 beam or additional support posts.

Conclusion

Understanding the factors affecting deck beam span is essential for designing and building a safe, durable deck. By considering variables such as wood type and grade, beam dimensions, joist spacing, and load requirements, you can select the appropriate beam size and configuration for your project. Always consult local building codes and, when in doubt, seek guidance from a professional to ensure your deck meets structural and safety standards. A well-planned deck not only enhances your outdoor living space but also provides years of enjoyment with peace of mind.