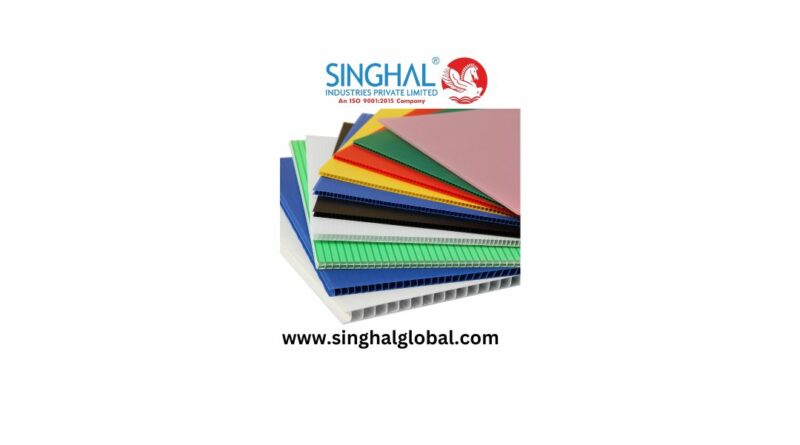

PP Sheets for Reliable and Efficient Industrial Applications

The Rising Demand for High-Performance Plastic Materials

The use of high-performance plastic materials has seen a significant rise in recent years due to their versatility, durability, and cost-effectiveness. These materials are widely utilized in various industries, including packaging, automotive, construction, and signage, owing to their excellent mechanical properties and resistance to chemicals and moisture. With advancements in polymer technology, industries are increasingly relying on lightweight yet sturdy solutions that meet their specific operational requirements PP Sheet Exporters in Gujarat ability to be easily fabricated, thermoformed, and customized for different applications further enhances their demand in the market.

Applications in the Packaging Industry

One of the primary applications of polymer-based sheets is in the packaging sector, where they provide high durability, flexibility, and moisture resistance. These materials are commonly used for creating protective layers, food containers, and industrial packaging solutions that require strength and longevity. Their ability to withstand temperature variations makes them suitable for food storage and medical applications. Additionally, they are widely preferred for transportation packaging due to their lightweight nature, reducing overall shipping costs and enhancing logistics efficiency. The demand for high-quality packaging materials is expected to grow as businesses seek reliable and cost-effective solutions.

Significance in the Construction and Automotive Sectors

The construction and automotive industries have increasingly adopted polymer-based solutions for a wide range of applications. These sheets offer excellent impact resistance, making them ideal for wall cladding, interior paneling, and protective barriers in building projects. In the automotive industry, they are used for interior trims, dashboard panels, and protective covers, contributing to lightweight vehicle design and improved fuel efficiency. Their resistance to corrosion, chemicals, and environmental conditions ensures long-term durability, making them a valuable choice for manufacturers and engineers seeking advanced materials for modern applications.

Environmental Advantages and Sustainability Factors

As environmental concerns continue to rise, industries are shifting towards sustainable and recyclable materials to reduce their ecological footprint. Many manufacturers now produce eco-friendly alternatives that can be reused and recycled, aligning with global sustainability goals. The recyclability of these materials helps in minimizing industrial waste while ensuring high-performance applications. By adopting responsible production practices, businesses contribute to environmental conservation while maintaining cost-effective operations. The development of biodegradable and low-impact materials further supports the transition towards sustainable industrial solutions.

Market Trends and Industrial Growth Prospects

The market for advanced plastic materials is witnessing rapid expansion due to increasing industrialization, infrastructural development, and technological advancements. Countries experiencing growth in manufacturing and exports are investing in high-quality polymer solutions to meet the demands of various industries. With advancements in PP Sheets Suppliers in India techniques, businesses can now produce materials with enhanced properties such as UV resistance, flame retardancy, and increased durability. The rising awareness of innovative material applications is expected to drive further demand, offering lucrative opportunities for industry players looking to expand their market reach.

Quality Standards and Customization for Industrial Use

Ensuring high-quality standards is essential for businesses that rely on polymer-based materials for production and packaging. Manufacturers adhere to strict quality control measures to meet industry regulations and customer requirements. Customization options, including varying thicknesses, surface finishes, and color choices, provide industries with tailored solutions that align with specific applications. By working with certified suppliers, businesses can obtain products that guarantee long-term performance, safety, and efficiency, making them an integral component of industrial operations.

Economic Benefits and Cost-Efficiency for Businesses

Investing in high-quality plastic solutions provides economic advantages for businesses by reducing operational costs and improving efficiency. Their lightweight nature contributes to lower transportation expenses, while their durability minimizes the need for frequent replacements. Additionally, their adaptability across multiple industries ensures maximum utility, making them a cost-effective choice for manufacturers. As industries focus on optimizing their supply chains, the use of advanced materials plays a crucial role in ensuring seamless operations and enhanced profitability.

Conclusion

The increasing reliance on high-performance plastic solutions highlights their importance in various industrial sectors. Their applications in packaging, construction, automotive, and logistics demonstrate their versatility and durability PP Sheets Manufacturer in Gujarat growing emphasis on sustainability and technological advancements, the demand for innovative materials is expected to rise further. Businesses investing in quality solutions can achieve enhanced product protection, operational efficiency, and long-term value. The evolving market trends indicate a promising future for industries that prioritize durable, customizable, and environmentally responsible materials.

Frequently Asked Questions

What are the key advantages of using these plastic materials?

These materials offer excellent durability, flexibility, and resistance to chemicals and moisture. Their lightweight nature and recyclability make them ideal for multiple industrial applications, including packaging, construction, and automotive manufacturing.

Are these materials environmentally friendly?

Many manufacturers focus on producing recyclable and sustainable alternatives to minimize environmental impact. By adopting eco-friendly production processes, industries can reduce waste and contribute to environmental conservation efforts.

Which industries benefit the most from these materials?

Industries such as packaging, construction, automotive, and logistics benefit significantly due to their high strength, cost-effectiveness, and adaptability. Their ability to withstand harsh environmental conditions makes them ideal for demanding applications.

What factors should be considered when selecting these materials?

Businesses should evaluate factors such as strength, thickness, chemical resistance, and intended application before making a selection. Choosing the right specifications ensures optimal performance, cost-efficiency, and long-term reliability.