Revolutionize Your Cleaning Process with Laser Cleaner: The Future of Surface Restoration

In today’s fast-paced world, efficiency and effectiveness are paramount in every cleaning process. Enter the laser cleaner, a cutting-edge technology that is transforming the way we think about surface restoration. Utilizing the power of laser technology, these innovative machines offer an unparalleled solution for various industries, from manufacturing to restoration and everything in between. Here’s why the laser cleaner should be your go-to solution for all your cleaning needs.

What is a Laser Cleaner?

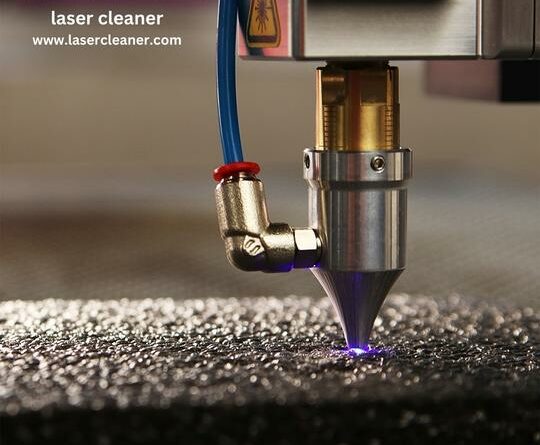

A laser cleaner is a state-of-the-art device that uses high-intensity laser beams to remove contaminants from surfaces. This technology harnesses the power of light to clean without chemicals or abrasives, making it an eco-friendly option. By emitting laser light onto a surface, the laser cleaner can effectively vaporize rust, paint, dirt, and other unwanted materials without damaging the underlying substrate. This precision cleaning method is suitable for various applications, including metal, wood, stone, and plastics.

Why Choose Laser Cleaning?

- Eco-Friendly Solution: One of the standout features of laser cleaners is their environmentally friendly approach. Traditional cleaning methods often rely on harsh chemicals and abrasive materials, which can harm the environment. In contrast, laser cleaning eliminates the need for these substances, reducing hazardous waste and ensuring a safer working environment.

- Versatile Applications: Laser cleaners are incredibly versatile and can be used across multiple industries. From automotive manufacturing and aerospace to historical restoration and art preservation, laser technology adapts to various cleaning needs. It’s ideal for removing corrosion from metal parts, cleaning delicate artworks, and restoring historical buildings without the risk of damage.

- Cost-Effective and Efficient: While the initial investment in a laser cleaning system may seem significant, the long-term savings are substantial. The efficiency of laser cleaning means less downtime for machinery and quicker turnaround times for projects. Moreover, the reduced need for consumables—like cleaning agents and abrasives—lowers operational costs significantly.

- Precision and Safety: Laser cleaners provide a level of precision that is difficult to achieve with traditional cleaning methods. The focused laser beam can selectively target contaminants, allowing for detailed cleaning in hard-to-reach areas. Additionally, because laser cleaning generates less heat and uses no chemicals, it minimizes the risk of injury to workers and damage to surfaces.

- Minimal Waste: Unlike traditional cleaning methods that produce substantial waste from chemicals and materials, laser cleaning generates minimal debris. The contaminants are typically vaporized, reducing the amount of cleanup needed post-cleaning. This not only saves time but also helps maintain a clean and organized workspace.

How to Get Started with Laser Cleaning

Investing in a laser cleaner is a step towards innovation and efficiency. Whether you’re a small business looking to improve your cleaning processes or a large enterprise seeking to optimize your operations, a laser cleaning system can provide the solution you need.

When considering a laser cleaner, look for reputable manufacturers that offer reliable products and comprehensive support. It’s essential to choose a system that fits your specific needs and can be easily integrated into your existing operations.

Conclusion

In conclusion, a laser cleaner represents the future of cleaning technology. With its eco-friendly approach, versatility, cost-effectiveness, precision, and minimal waste generation, it’s an investment that can revolutionize your cleaning process. Embrace this innovative solution today, and witness the transformation in how you approach surface restoration. Experience the power of laser cleaning and join the movement toward a cleaner, safer, and more efficient future.