The Ultimate Guide to Choosing the Right Slitter Cutter for Your Needs

When it comes to industrial cutting, one of the most essential tools is a slitter cutter. Whether you’re in packaging, food processing, textile cutting, or any other industry, selecting the right slitter cutter can significantly impact the quality of your work, the efficiency of your production, and even the longevity of your equipment. In this guide, we’ll explore key factors to consider when choosing slitter cutters for your needs and help you make an informed decision.

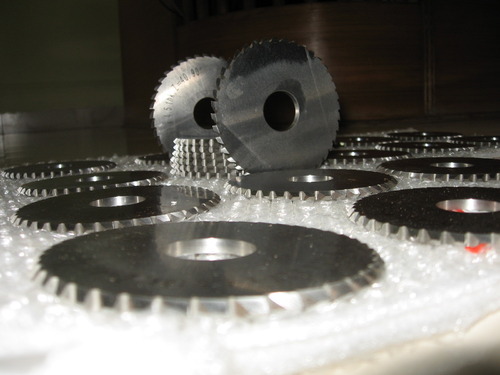

What is a Slitter Cutter?

A slitter cutter is a specialized tool used to cut materials such as paper, plastic, rubber, or textiles into narrow strips. The cutting process typically involves a rotary or circular blade that slices through the material with precision. Slitter cutters are essential for converting large rolls of material into smaller, uniform widths, making them a key component in many industries like packaging, automotive, and even food processing.

Factors to Consider When Choosing a Slitter Cutter

1. Material Type

The type of material you need to cut is one of the most important factors in choosing the right slitter cutter. Different materials require different cutting methods, blade types, and blade coatings.

- Paper and Cardboard: For materials like paper and cardboard, you’ll want a slitter cutter with a sharp, durable blade to handle the tough, fibrous nature of these materials.

- Plastic and Rubber: Slitting plastic and rubber requires cutters that can withstand heat and resist wear. Choosing blades made of high-speed steel or carbide can enhance the cutter’s performance in such applications.

- Textiles: When cutting textiles, you need a slitter cutter designed for precision and minimal damage to the fabric. Blades with smooth edges are ideal for these applications.

2. Cutting Speed

The speed at which you need to cut materials depends on your production demands. Faster cutting speeds are ideal for high-volume operations, but they also come with the need for more durable blades and machines. If your cutting process is slower, a high-quality, sharp blade may be enough.

When choosing a slitter cutter, it’s essential to match the machine’s cutting speed with the type of material being processed and the desired output. Some cutters are designed for high-speed, continuous production, while others are better suited for slower, more precise cuts.

3. Blade Material and Durability

The longevity of your slitter cutter depends largely on the type of blade material used. Some common blade materials include:

- High-Speed Steel (HSS): HSS blades are popular for their durability and ability to handle high cutting speeds. They’re great for cutting tougher materials like rubber, plastic, and metals.

- Carbide-Tipped Blades: Carbide blades are ideal for industries that require long-lasting performance, like the packaging or paper industry. They maintain sharpness longer and can withstand tougher applications.

- Stainless Steel: For non-abrasive materials like paper and textiles, stainless steel blades can be a good choice as they offer a combination of strength and resistance to corrosion.

Choosing the right blade material based on the intended application is crucial for optimizing the slitter cutter’s lifespan and performance.

4. Precision and Tolerances

Precision is another key consideration, especially in industries where consistency and uniformity are critical. When choosing a slitter cutter, consider the level of precision required for your cuts.

- Rotary Slitter Cutters provide continuous, precise cuts and are well-suited for high-volume, high-accuracy applications.

- Shear Slitter Cutters offer high precision and are perfect for applications requiring minimal material wastage.

The type of slitter cutter should align with your specific requirements for cut accuracy and tolerances.

5. Adjustability and Versatility

Depending on your operations, you may need a slitter cutter that is flexible enough to handle different materials or adjust for different cutting widths. Some slitter cutters come with adjustable settings, allowing you to change the blade position and cutting speed.

If your operations require frequent changes in material size or cutting width, a versatile slitter cutter with easy adjustments can save you time and improve efficiency.

6. Maintenance and Costs

Like any piece of industrial equipment, slitter cutters require regular maintenance. Choose a model that allows for easy maintenance, with readily available spare parts. Routine maintenance is essential to ensure that the slitter cutter stays in good working condition and delivers optimal performance.

Also, consider the overall cost of the slitter cutter, including initial investment, maintenance, and operational costs. While high-quality cutters may come with a higher upfront price, their durability and performance can make them a more cost-effective option in the long run.

7. Safety Features

Safety is paramount when dealing with industrial cutting equipment. Look for slitter cutters that include built-in safety features such as blade guards, emergency stop functions, and safety interlocks. These features can help prevent accidents and ensure a safer working environment for operators.

8. Automation and Control

For businesses looking to maximize efficiency, consider slitter cutters with automated functions and digital control systems. Automated slitting machines can improve accuracy, reduce human error, and speed up the cutting process, making them a valuable asset in high-volume production lines.

Choosing the Right Manufacturer

Once you’ve determined your needs, it’s essential to choose the right manufacturer. Look for manufacturers who specialize in slitter cutters and offer high-quality, durable products. Ensure that they provide customer support, and that they can help with customization if your needs are unique. Maxwell Slitter Industries, for example, offers custom precision wear parts and a wide range of slitter cutters designed to meet the demands of various industries.

Wrapping it Here

Choosing the right slitter cutter is crucial for optimizing your production processes. By considering factors such as material type, blade durability, cutting speed, precision, and safety, you can make an informed decision that improves your workflow and product quality. Always consult with an expert or a trusted manufacturer to find the best solution for your specific needs. With the right slitter cutter, you’ll be equipped to meet your industrial cutting challenges head-on.