Why Industries Prefer Oil Fired Steam Boilers?

In industrial applications, efficiency, reliability, and cost-effectiveness are paramount when selecting steam boilers. Oil fired steam boilers have gained significant traction across a range of industries, including manufacturing, chemical processing, food production, and pharmaceuticals. These boilers are favored for their ability to provide high-pressure steam, which is essential for various industrial processes. In this article, we will explore why industries prefer oil fired steam boilers, focusing on their benefits, key features, and their role in enhancing productivity and operational efficiency.

What is an Oil Fired Steam Boiler?

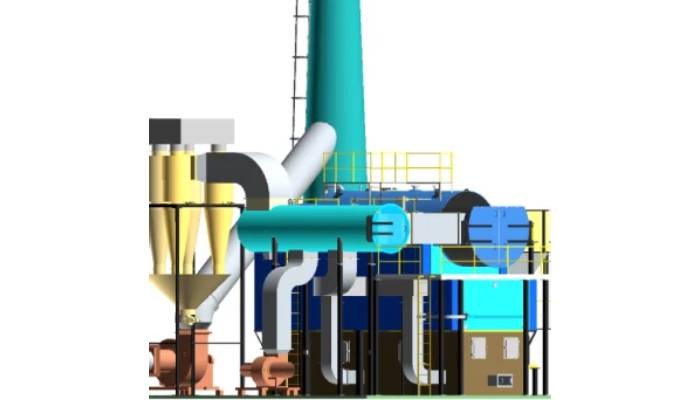

An oil fired steam boiler is a system that uses oil as a fuel source to heat water, producing steam. The heat generated by burning the oil is transferred to the water in the boiler, causing it to vaporize into steam. This steam is then used in a variety of industrial applications, from heating to power generation and manufacturing processes. These boilers come in various configurations, such as fire-tube, water-tube, and modular designs, each suited to different operational needs.

Energy Efficiency and Performance

One of the most significant reasons industries prefer oil fired steam boilers is their energy efficiency. Oil has a high calorific value, which means it can produce a large amount of heat energy per unit of fuel. When used in a well-maintained oil fired steam boiler, this results in high thermal efficiency. This increased efficiency translates into more steam production with less fuel consumption, ultimately reducing operational costs.

Moreover, modern oil fired steam boilers are designed to maximize energy efficiency through advanced features such as:

- Burner technology: Latest burners are designed to ensure optimal combustion, leading to higher efficiency and reduced fuel consumption.

- Heat recovery systems: Many oil fired steam boilers feature heat recovery units that capture and reuse the heat energy, improving the overall energy balance.

These efficiency improvements not only help industries save on energy costs but also reduce the environmental impact by minimizing fuel consumption.

Consistent and Reliable Steam Supply

A reliable steam supply is critical for industries that rely on steam for their processes. Oil fired steam boilers are known for their consistency in delivering steam at the required pressure and temperature. In industries such as food production, pharmaceuticals, and chemical manufacturing, where steam is a crucial component of the production process, any interruption in steam supply can cause significant delays, waste, and even product defects.

Oil fired steam boilers can operate continuously for long periods, making them a reliable choice for industries with high steam demand. Their ability to quickly adjust to changing load requirements ensures that the steam supply remains stable, which is particularly beneficial in industries that require a constant and uninterrupted supply of steam.

Flexibility and Fuel Availability

Another key advantage of oil fired steam boilers is the flexibility in fuel usage. Oil is widely available in many parts of the world, and industries located in areas where natural gas infrastructure is not readily accessible can still rely on oil as a dependable fuel source. Furthermore, oil is compatible with different types of boilers, from small-scale systems to large industrial models, offering businesses scalability and flexibility based on their steam requirements.

Additionally, oil can be stored on-site in large quantities, providing industries with the benefit of a continuous fuel supply, even during supply chain disruptions. This makes oil fired steam boilers a particularly attractive option for industries that need a secure and uninterrupted fuel source.

Lower Initial Investment Costs

When compared to natural gas-fired or electric boilers, oil fired steam boilers often come with lower initial investment costs. Although operational costs may vary depending on fuel prices, the capital expenditure for oil fired steam boilers is usually more budget-friendly, especially for smaller industries or businesses just starting.

The relatively low upfront costs, combined with the long lifespan of these boilers, make them an economical choice for many industries. This is especially beneficial for businesses looking to avoid high capital expenses while still benefiting from reliable steam production.

Simplicity of Operation and Maintenance

Oil fired steam boilers are known for their straightforward operation and maintenance needs. These systems typically have fewer complex components compared to gas or electric boilers, making them easier to operate and maintain. For industries that need to keep operational downtime to a minimum, this simplicity can be a significant advantage.

- Ease of maintenance: Oil fired steam boilers require regular servicing, but maintenance tasks such as checking burner operation, cleaning the heat exchangers, and monitoring the fuel system are relatively simple.

- Longer lifespan: When properly maintained, oil fired steam boilers can last for decades, providing a return on investment over a long period.

Moreover, many oil fired steam boilers are designed with features that make maintenance even more convenient, such as easy-to-replace parts and diagnostic systems that help identify potential issues before they become critical.

Environmental Considerations and Emissions Control

While burning oil does produce carbon emissions, advancements in technology have made oil fired steam boilers more environmentally friendly. Modern oil burners are equipped with efficient combustion systems that minimize particulate emissions and reduce the overall environmental impact.

Additionally, industries are increasingly focusing on adopting boilers that comply with environmental standards and regulations. Some oil fired steam boilers are designed with emissions control technologies, such as:

- Flue gas treatment systems: These systems capture and neutralize harmful emissions, such as nitrogen oxides (NOx) and sulfur dioxide (SO2), reducing their release into the atmosphere.

- Dual fuel options: Many oil fired steam boilers can operate on both oil and gas, providing flexibility and enabling businesses to switch to a cleaner fuel source when necessary.

While oil is not the cleanest fuel option, these technological advancements allow industries to balance operational needs with environmental concerns.

Use in a Wide Range of Applications

Oil fired steam boilers are versatile and can be used across a wide variety of industrial applications. Some of the key sectors that benefit from oil fired steam boilers include:

- Manufacturing: Industries that rely on steam for heat processing, sterilization, and power generation.

- Food and Beverage: Boilers provide steam for cooking, cleaning, and pasteurization in the food production process.

- Pharmaceuticals: Steam is essential in sterilizing equipment and creating controlled environments for the manufacturing of pharmaceutical products.

- Textiles: Steam is used in dyeing, washing, and finishing processes in the textile industry.

The ability to meet the steam requirements of such diverse industries is a key reason why oil fired steam boilers are so popular.

Conclusion

Oil fired steam boilers remain a preferred choice for many industries due to their reliability, efficiency, and cost-effectiveness. These systems provide a steady and reliable steam supply, require less initial investment, and are relatively simple to maintain. Moreover, their flexibility in fuel usage and ability to operate efficiently make them ideal for industries with varying steam demands.

As technology continues to advance, oil fired steam boilers will continue to evolve, offering even better efficiency and environmental performance. For industries seeking a dependable, cost-effective, and scalable solution for their steam needs, oil fired steam boilers present a compelling option.