Why Should You Invest in a Jumbo Bag Filling Machine for Your Business?

If your business deals with bulk materials like grains, powders, fertilizers, or construction aggregates, you probably know the challenges of packaging large quantities efficiently. Manually filling jumbo bags can be time-consuming, inconsistent, and labor-intensive. That’s why many businesses are turning to automation—specifically, a jumbo bag filling machine—to streamline their operations.

But how does this machine work, and what benefits can it offer? Let’s explore why investing in a jumbo bag filling machine could be a game-changer for your business.

What is a Jumbo Bag Filling Machine?

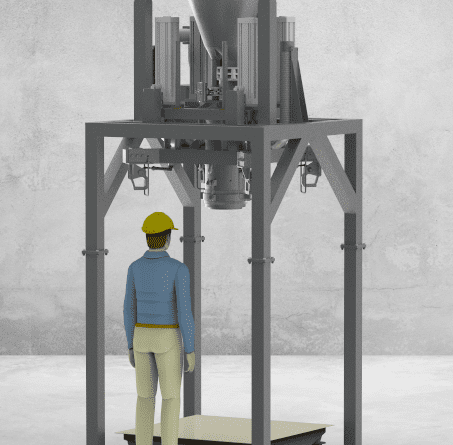

A jumbo bag filling machine is a specialized industrial machine designed to fill large bulk bags—also known as FIBCs (Flexible Intermediate Bulk Containers), super sacks, or big bags—with various materials. It automates the bag-filling process, ensuring accurate weight measurements, minimizing waste, and improving efficiency.

These machines are widely used in industries such as agriculture, food processing, construction, mining, and chemicals. Whether you’re dealing with fine powders, granules, or coarse materials, a jumbo bag filling machine can handle the job with precision.

How Does a Jumbo Bag Filling Machine Work?

The process of filling a jumbo bag using this machine is straightforward, but the automation significantly improves efficiency. Here’s how it works:

- Bag Attachment: The operator secures an empty jumbo bag onto the machine’s filling spout. Some machines have automatic bag clamps to hold it in place securely.

- Material Dispensing: The machine releases material into the bag through a controlled feed system, ensuring an even flow without excessive dust or spillage.

- Weighing System: A built-in scale monitors the weight of the bag in real time, stopping the filling process once the target weight is reached.

- Vibration & Settling (Optional): Some models include a vibration feature to settle the material evenly, reducing air pockets and maximizing storage capacity.

- Sealing & Removal: Once the bag is filled, it is sealed and detached, ready for transport or storage.

This fully automated process reduces the need for manual labor and improves overall packaging efficiency.

Industries That Benefit from a Jumbo Bag Filling Machine

A jumbo bag filling machine is useful in various industries, helping businesses improve their bulk material handling. Here are some key industries that benefit from this technology:

- Agriculture: Farmers and suppliers use these machines to package grains, seeds, animal feed, and fertilizers quickly and accurately.

- Food Processing: Bulk ingredients like flour, sugar, rice, and coffee beans require precise weighing and packaging to maintain quality standards.

- Construction & Mining: Heavy materials such as sand, cement, and gravel need efficient bagging to ensure safe transport and storage.

- Chemicals & Pharmaceuticals: Powders, industrial chemicals, and pharmaceutical ingredients require careful measurement and safe packaging.

- Recycling & Waste Management: Recyclable materials, including plastic pellets, shredded paper, and scrap metal, can be bagged for easy handling and transport.

No matter what bulk material your business handles, a jumbo bag filling machine can significantly improve your packaging process.

Key Benefits of Using a Jumbo Bag Filling Machine

1. Increased Efficiency & Productivity

Manually filling jumbo bags is time-consuming. A jumbo bag filling machine automates the process, allowing you to fill more bags in less time, boosting overall productivity.

2. Accurate Weighing & Reduced Waste

Overfilling or underfilling bags can lead to product loss or inconsistencies. The integrated weighing system ensures precise measurement, reducing waste and ensuring uniformity in each bag.

3. Lower Labor Costs

Automating the bagging process reduces reliance on manual labor. This not only cuts labor costs but also allows employees to focus on other essential tasks within your business.

4. Improved Workplace Safety

Handling heavy materials manually can lead to injuries. A jumbo bag filling machine minimizes the need for manual lifting, creating a safer work environment for employees.

5. Cleaner & More Organized Work Area

Manual bagging often results in spills and material loss, making cleanup a hassle. With controlled filling and dust reduction features, the machine keeps your work area clean and organized.

6. Versatility for Different Materials

A jumbo bag filling machine can be customized to handle various types of materials, from fine powders to large aggregates, making it a versatile solution for different industries.

How to Choose the Right Jumbo Bag Filling Machine

If you’re considering investing in a jumbo bag filling machine, here are some important factors to keep in mind:

- Type of Material: Make sure the machine is designed to handle the specific materials you work with. Some models are better suited for powders, while others are ideal for heavier granules or aggregates.

- Filling Speed: If your production demands are high, look for a machine with a fast filling rate to meet your operational needs.

- Weighing Accuracy: Precision is crucial in bulk packaging. Choose a machine with an advanced weighing system to minimize material loss.

- Additional Features: Consider extra features like dust control, vibration systems, and automatic bag sealing for improved efficiency.

- Space & Layout Compatibility: Ensure that the machine fits within your facility and integrates seamlessly with your existing production line.

Future Trends in Jumbo Bag Filling Machines

With advancements in technology, jumbo bag filling machines are becoming smarter and more efficient. Here are some emerging trends shaping the future of bulk packaging:

- IoT-Enabled Monitoring: Smart machines can connect to the internet, allowing real-time tracking of production data, maintenance schedules, and operational performance.

- AI-Powered Weighing Systems: Artificial intelligence is helping machines optimize weight accuracy, adapting to variations in material density.

- Eco-Friendly Packaging Solutions: More companies are moving towards sustainable packaging, and machines are being designed to support biodegradable and recyclable bulk bags.

- Compact & Mobile Designs: Businesses are looking for flexible solutions, leading to the development of portable jumbo bag filling machines that can be easily relocated based on production needs.

Is a Jumbo Bag Filling Machine Right for Your Business?

If your business regularly handles large quantities of materials, investing in a jumbo bag filling machine is a smart decision. The benefits include:

- Faster, more efficient packaging

- Improved accuracy and reduced waste

- Lower labor costs and increased productivity

- A safer, cleaner, and more organized work environment

By automating your bulk packaging process, you can optimize efficiency, reduce costs, and enhance overall operations.

Conclusion

A jumbo bag filling machine isn’t just a luxury—it’s a necessity for businesses that deal with bulk materials. Whether you work in agriculture, construction, food processing, or manufacturing, this machine can transform the way you handle packaging, making your operations smoother and more cost-effective.

Are you ready to take your packaging process to the next level? Investing in a jumbo bag filling machine could be the solution you’ve been looking for.