What role do pores play in material airflow characteristics?

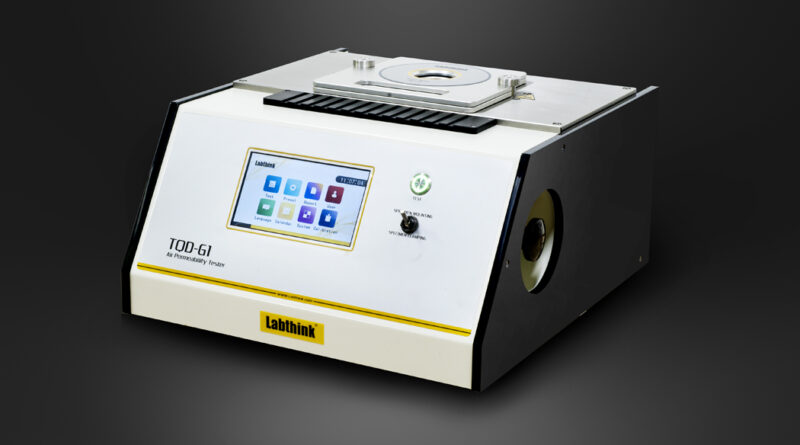

Understanding how air flows through materials is crucial, especially for industries dealing with filtration, ventilation, and textiles. One of the key factors influencing airflow in these materials is the presence and characteristics of pores, which are often measured using tools like an air permeance tester membrane pore. But what exactly are pores, and how do they affect the way air moves through various substances? Let’s take a deep dive into the role pores play in material airflow characteristics and how this impacts the materials we use in everyday life.

What Are Pores in Materials?

Pores are tiny openings or voids within a material. Depending on the material type, these pores can vary in size, distribution, and shape. They create pathways that allow air (or other gases) to pass through the material. Think of pores as tunnels or channels through which air moves. The number, size, and arrangement of these pores determine how much air can pass through and how quickly it moves.

Why Pore Size Matters for Airflow

The size of the pores in a material directly influences its airflow characteristics. Materials with large pores allow more air to pass through easily, resulting in higher permeability. On the other hand, smaller pores restrict the airflow, making the material less permeable. This relationship between pore size and airflow is essential in applications such as air filters, where controlling the amount of air that passes through is crucial.

How Pore Shape Affects Air Movement

Not all pores are created equal when it comes to shape. Some pores are round, while others may be elongated or irregular. The shape of the pores can affect how air flows through a material. Round pores tend to allow smoother airflow, while elongated or irregularly shaped pores may create turbulence, slowing down the airflow. In materials like foam or textiles, the pore shape is intentionally designed to either facilitate or hinder airflow, depending on the desired outcome.

The Relationship Between Pore Distribution and Airflow

Pore distribution refers to how pores are spread across a material’s surface or throughout its structure. Evenly distributed pores generally promote consistent airflow, while unevenly distributed pores can lead to areas where airflow is faster or slower. For example, a material with tightly clustered pores in one region may restrict airflow in that area, while allowing more air to pass through less dense areas. This uneven distribution can be useful in specialized applications like targeted ventilation.

Pore Connectivity and Its Impact on Airflow

In some materials, the pores are connected, forming continuous pathways for air to travel through. This pore connectivity enhances the material’s permeability and allows air to flow more freely. On the other hand, if the pores are isolated or blocked, airflow is restricted. Infiltration materials, for example, controlling the connectivity of pores helps to balance between effective filtration and efficient airflow.

Material Thickness and Pore Characteristics

Material thickness also plays a vital role in how pores influence airflow. Thicker materials generally have more resistance to airflow, as air has to travel through more layers of pores. However, if the pores in a thick material are large and well-connected, air can still pass through with relative ease. On the flip side, thin materials with small or poorly connected pores may still offer high resistance to airflow. Therefore, both the thickness and pore structure need to be considered when designing materials for specific airflow characteristics.

How Porosity Affects Airflow

Porosity refers to the proportion of a material’s volume that is made up of pores. Materials with high porosity have a greater percentage of their volume filled with air, making it easier for air to flow through. In contrast, low-porosity materials have fewer pores, limiting the air passage. This principle is applied in industries like textile manufacturing and insulation, where controlling the airflow through materials is essential for comfort, energy efficiency, and product performance.

The Role of Pores in Air Filters

One of the most practical applications of pores in materials is found in air filters. Filters are designed with specific pore sizes and distributions to either allow or block particles from passing through while maintaining optimal airflow. For instance, a HEPA filter uses small pores to trap tiny particles like dust, pollen, and bacteria while still allowing air to flow through the material. The balance between pore size and airflow in such filters ensures that the air remains clean without creating too much resistance.

Pores in Breathable Fabrics

Pores also play a critical role in the breathability of fabrics. In clothing, especially sportswear or outdoor gear, materials with the right pore structure allow sweat and moisture to escape while letting air circulate. This creates a cooling effect, keeping the wearer comfortable. Fabrics with smaller pores may restrict airflow, causing heat and moisture to build up, while materials with larger or more open pores provide better ventilation.

Optimizing Pore Structure for Desired Airflow

The ability to tailor pore structure—whether by altering size, distribution, or connectivity—gives manufacturers control over the airflow properties of their materials. For example, in the construction industry, building materials with optimal pore sizes and distributions can enhance ventilation and insulation, improving energy efficiency. Similarly, in medical applications, materials with controlled pore structures are used in bandages or wound dressings to allow air to pass through while preventing infections.

Advanced Materials and Pore Engineering

With advances in material science, engineers and designers can now create materials with highly specialized pore structures that meet specific airflow needs. This process, known as pore engineering, involves designing and manipulating pores to achieve desired permeability levels. From synthetic membranes used in air and water filtration to nanomaterials that regulate airflow at a microscopic level, the possibilities for using pores to control airflow are expanding rapidly.

Conclusion

In summary, pores play a crucial role in determining the airflow characteristics of materials. Whether it’s the size, shape, distribution, or connectivity of these pores, they all influence how air moves through a material. Industries from filtration to fashion rely on understanding and controlling these airflow characteristics to create products that meet specific needs. By optimizing pore structure, we can enhance comfort, efficiency, and performance in a wide range of applications.

![[tiktokio.cam] Tiktokio-Tiktok Downloader](https://nichenest.xyz/wp-content/uploads/2025/01/tiktokio.cam-Tiktokio-Tiktok-Downloader-390x205.png)