Water Stopper: A Critical Component in Preventing Water Damage in Construction and Infrastructure

Introduction

Water damage can cause significant structural issues in buildings and infrastructure, leading to costly repairs, safety hazards, and the degradation of materials. Preventing water infiltration in construction projects is essential to maintaining the longevity and integrity of the structure. A water stopper, also known as a waterstop, is an essential tool used in the construction and civil engineering industries to prevent water penetration through joints, cracks, and seams in concrete. Water stoppers are commonly employed in areas that are exposed to high levels of moisture or water pressure, such as basements, tunnels, swimming pools, dams, and wastewater treatment plants. This article will explore what a water stopper is, its different types, how it works, its applications, and the advantages of using water stoppers in various construction projects.

What is a Water Stopper?

A water stopper is a material or device that is installed in construction joints to prevent the passage of water through the joint or crack. These stoppers are designed to act as a barrier that blocks water from seeping through gaps, cracks, or seams in concrete structures, helping to ensure the structural integrity of the building or infrastructure. Water stoppers are used to protect the structure from the damaging effects of water infiltration, which can lead to corrosion, weakening of the structure, mold growth, and other forms of damage over time.

Water stoppers are typically installed at the construction joints between two adjacent concrete sections. These joints are the most vulnerable points where water can seep in, especially when the concrete is subject to high water pressure or fluctuating environmental conditions. By providing a reliable seal, water stoppers help to prevent water from infiltrating the structure and ensure that the concrete remains dry and intact.

How Do Water Stoppers Work?

Water stoppers work by creating an impermeable barrier that blocks the passage of water through the construction joints. These barriers are made from materials that are resistant to water and pressure, such as rubber, PVC, and hydrophilic compounds. When installed correctly, a water stopper forms a tight seal around the joint or crack, preventing water from passing through even under high pressure.

There are different types of water stoppers, each designed to address specific conditions or requirements. The function of each water stopper depends on the type of material used, the environment in which it is installed, and the specific water infiltration challenges it aims to address.

Types of Water Stoppers

Water stoppers are available in various forms and materials, each suited for different construction needs. Some of the most common types of water stoppers include:

- Rubber Waterstops

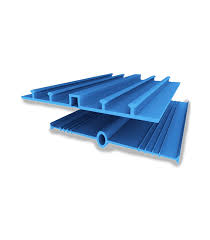

Rubber waterstops are one of the most widely used types of waterstops in construction projects. They are typically made from a combination of natural and synthetic rubber compounds that are flexible, durable, and resistant to water, chemicals, and UV radiation. Rubber waterstops are designed to be installed in expansion joints, cold joints, and construction joints in concrete structures. Their flexibility allows them to accommodate movement in the concrete while maintaining a tight seal against water infiltration. - PVC Waterstops

Polyvinyl chloride (PVC) waterstops are another popular type of water stopper used in construction. PVC waterstops are lightweight, cost-effective, and resistant to water and chemicals. They are often used in projects where water pressure is moderate, such as in swimming pools, sewage treatment plants, and basement walls. PVC waterstops are available in various shapes, including single and multi-ribbed designs, to provide better sealing performance at the joints. - Hydrophilic Waterstops

Hydrophilic waterstops are designed to expand when they come into contact with water. These waterstops are made from materials that swell upon hydration, creating a tight seal that prevents water from passing through. Hydrophilic waterstops are commonly used in areas exposed to high water pressure or where there is a risk of water infiltration due to fluctuating water levels. The ability to expand in the presence of water makes them ideal for use in underground structures, tunnels, and other water-exposed areas. - Metal Waterstops

Metal waterstops are typically made from stainless steel or other corrosion-resistant metals. They are used in high-pressure applications where other types of waterstops might not provide adequate sealing. Metal waterstops are commonly used in dam construction, reservoirs, and heavy industrial applications where extreme conditions are present. - Bentonite Waterstops

Bentonite waterstops are made from a type of clay that swells when exposed to water. Bentonite is a naturally occurring material that forms a gel-like consistency when hydrated, which helps to seal construction joints effectively. Bentonite waterstops are often used in underground construction, where they can provide an effective seal against groundwater infiltration. These waterstops are particularly effective in sealing joints in structures like tunnels and underground reservoirs. - Preformed Waterstops

Preformed waterstops are fabricated waterstops that come in pre-shaped forms, making them easier and faster to install. These waterstops are often used in applications where precise fitting is required, such as in areas with complex joint configurations. Preformed waterstops are available in various materials, including rubber, PVC, and hydrophilic compounds, and can be custom-designed to meet the specific requirements of a project.

Applications of Water Stoppers

Water stoppers are used in a wide range of construction projects to protect structures from water damage and infiltration. Some of the most common applications of water stoppers include:

- Basements and Underground Structures

Basements and other underground structures are highly susceptible to water infiltration due to their exposure to groundwater. Water stoppers are installed in the joints of concrete walls, floors, and foundations to prevent water from entering the structure. Properly installed waterstops can help prevent leaks, mold growth, and structural damage in these sensitive areas. - Swimming Pools

Swimming pools are exposed to constant water pressure, making them prone to water leakage. Water stoppers are used in the construction of pool walls, floors, and joints to prevent water from leaking out of the pool structure. They help ensure the pool’s structural integrity and prevent the surrounding environment from being damaged by water leakage. - Tunnels and Underground Transport Systems

Tunnels and underground transport systems, such as subways, metro lines, and utility tunnels, are subjected to high water pressure and exposure to groundwater. Waterstops are used to seal joints between concrete sections, preventing water from infiltrating the tunnel and causing structural damage. The use of waterstops in tunnels is crucial for ensuring the safety and longevity of the infrastructure. - Water Treatment Plants

Water treatment plants process large volumes of water, and the potential for leaks or water infiltration can cause significant operational issues. Waterstops are installed in construction joints within the plant to prevent water from leaking into the surrounding environment or other parts of the facility. Proper sealing is essential to maintain the efficiency of water treatment operations. - Dams and Reservoirs

Dams and reservoirs are built to contain large quantities of water, and the risk of water leakage or seepage is always a concern. Waterstops are installed in the construction joints of these structures to prevent water from leaking out and to ensure the stability and safety of the dam. The use of waterstops is critical in maintaining the integrity of these large-scale water control systems. - Sewage and Drainage Systems

Sewage treatment plants and drainage systems are exposed to water and wastewater on a constant basis. Waterstops are used in the construction of these systems to prevent leakage, infiltration, and contamination. They help ensure that the treated water remains contained within the system and does not leak into the surrounding environment.

Advantages of Using Water Stoppers

The use of water stoppers in construction offers several key advantages, including:

- Prevention of Water Damage

The primary function of water stoppers is to prevent water from infiltrating the structure. This is critical for maintaining the structural integrity of the building or infrastructure, as water infiltration can cause corrosion, weakening of materials, and mold growth. - Cost Savings

By preventing water damage, water stoppers can help save on costly repairs and maintenance that may otherwise be required to fix leaks and water-related issues. Proper installation of waterstops can reduce the need for ongoing repairs and help extend the lifespan of the structure. - Enhanced Safety

Water infiltration can weaken the structural components of a building, making it more vulnerable to damage or collapse. Water stoppers provide an effective solution for maintaining the safety and stability of the structure by preventing water penetration. - Long-Term Durability

Water stoppers are designed to be durable and long-lasting. They are made from high-quality materials that are resistant to water, chemicals, and environmental stress. This ensures that they will continue to perform their function effectively for many years, providing long-term protection for the structure.

Conclusion

Water stoppers are an essential component in preventing water infiltration and damage in construction projects. With various types of water stoppers available, each designed to meet specific requirements, construction professionals can choose the most appropriate solution for their project. Whether used in basements, swimming pools, tunnels, or water treatment plants, waterstops provide an effective and reliable method for ensuring the long-term stability and integrity of concrete structures. By preventing water penetration, water stoppers help safeguard the safety, durability, and functionality of infrastructure, ultimately reducing the risk of costly repairs and ensuring that buildings and other structures remain safe and secure for years to come.